CAD/CAM software has revolutionized the way manufacturing takes place. It is a computer technology that is used for designing and manufacturing products. It allows designers to create prototypes of products before they are actually manufactured. It is a vital technology for the manufacturing industry, allowing for more precise and efficient production. Over the past few years, there have been significant advancements in CAD/CAM software, and this article will explore those advancements.

One of the most significant advancements in CAD/CAM software is the ability to integrate with other software systems. Many CAD/CAM systems can now integrate with ERP systems, allowing companies to manage their entire business processes from one central location. This integration eliminates redundant processes and reduces the risk of errors. It also enables companies to track and manage their inventory and supply chain, ensuring that production is always on time.

Another significant advancement in CAD/CAM software is the use of cloud technology. The cloud is a central hub where data can be stored and accessed from anywhere in the world. Cloud CAD/CAM software allows designers to collaborate on projects in real-time, regardless of where they are located. This results in faster design iterations, improved communication, and reduced project timelines. Cloud-based CAD/CAM software also allows manufacturing companies to scale up or down their production capacity quickly.

3D printing has also been a game-changer in the manufacturing industry. CAD/CAM software has played an essential role in the development of 3D printing. With CAD/CAM software, designers can create a 3D model of a product and then print it out using a 3D printer. This technology has opened up a world of possibilities for prototyping and manufacturing. 3D printing reduces waste, reduces production time, and enables customization.

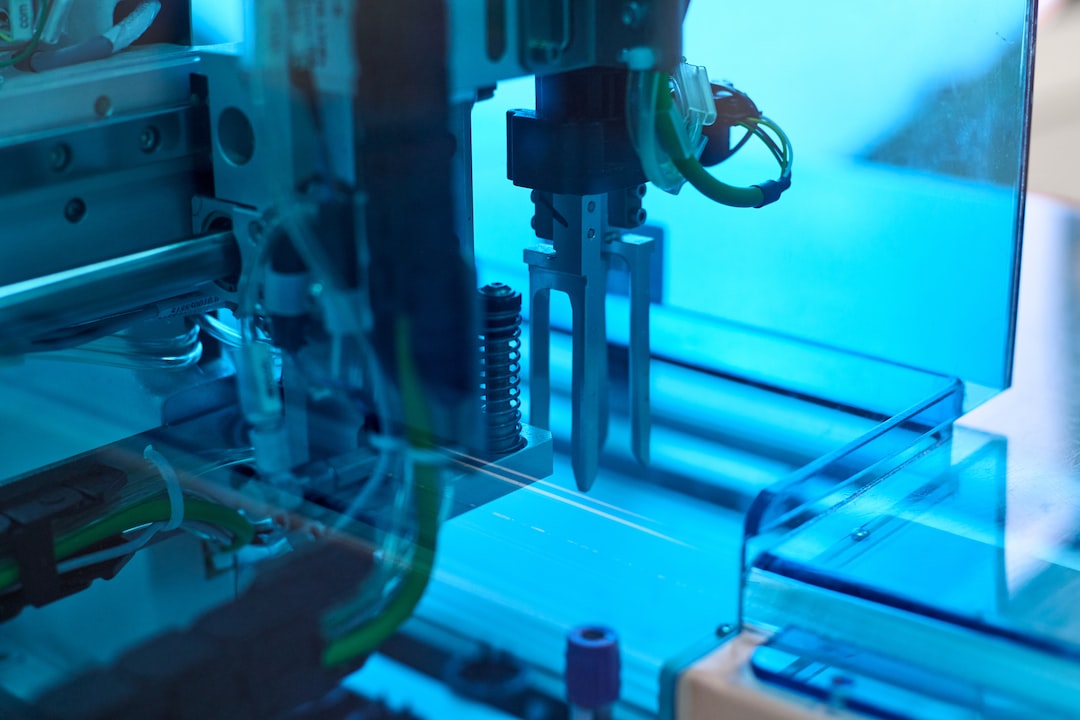

Automation is another area where CAD/CAM software has made significant advancements. Many manufacturing companies are now using robots to perform tasks that are dangerous or repetitive. CAD/CAM software can be used to program automated machines, resulting in more precise and faster production. Automation also reduces labor costs and increases production capacity.

Finally, artificial intelligence (AI) is another area where CAD/CAM software has made significant advancements. AI can be used to analyze large amounts of data and provide insights into production processes. This data can be used to improve product quality, reduce waste, and increase efficiency. AI can also be used to predict maintenance needs for machines, reducing downtime and improving overall productivity.

In conclusion, CAD/CAM software has come a long way in recent years, and the advancements in this technology are reshaping the manufacturing industry. Cloud technology, automation, 3D printing, and AI are just a few of the areas where CAD/CAM software has made significant advancements. As manufacturing companies continue to seek ways to improve efficiency and productivity, CAD/CAM software will undoubtedly play a vital role in achieving those goals.